Category:

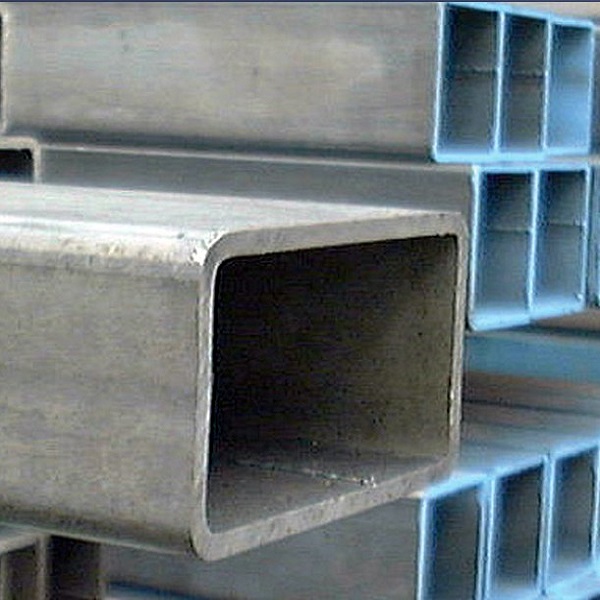

Rectangular Steel Tube

OD: 20X20-600X600MM

Grade: Q195,Q215,Q235,Q345, S275JR, S355JR, 355JOH, 355J2H

Thickness: 2-25MM

Surface: Oiled, Painted, Black, Galvanized

Product description:Hollow structural profile (HSS) is a kind of metal profile with a hollow cross-section.

Q235B Q355B Q355D Black Welded Carbon Rectangular Hollow Section RHS

Item

Rectangular Steel Pipe

OD

20x20-600x600mm

Thickness

2-25mm

Applicant

Fluid Pipe, Boiler Pipe, Drill Pipe, Hydraulic Pipe, Gas Pipe, OIL PIPE, Chemical Fertilizer Pipe

Alloy or Not

Non-Alloy

Section Shape

Rectangular

Standard

BS, GB, EN, JIS

Grade

Q195,Q215,Q235,Q345, S275JR, S355JR, 355JOH, 355J2H

Surface Treatment

Hot Rolled

Oiled or Non Oiled

Non-oiled

Delivery Time

15-30 days

Surface

Blace, Oild, Painted, Galvanized

Rectangular hollow sections(RHS) Production Process:

1. Raw material preparation

Steel coils or plates: Most RHS are made of hot-rolled or cold-rolled steel coils/plates.

Slitting and cutting: The coil is slitted to the required width before forming.

2. RHS forming method

There are mainly two manufacturing processes:

A. Welding (ERW/SAW/Laser welding) method

B. Roll forming (cold forming)

The steel belt is gradually bent into a rectangle through a series of rollers.

These edges come together to form a closed part.

3. Welding seam

Resistance welding (ERW) : High-frequency current fuses the edges.

Submerged arc welding (SAW) : Used for thick-walled RHS (commonly found in structural applications).

Laser welding: Used for high-precision, thin-walled RHS (commonly found in automotive/aerospace).

4. Sizing and setting

The welded pipe passes through the sizing roller to achieve precise dimensions.

5. Cooling and straightening

The RHS is cooled and straightened to eliminate deformation.

6. Cut to length

Continuous tubes are cut to the required length.

B. Seamless method (uncommon in RHS)

It is mainly used for round pipes (CHS), but some specialized RHS can be:

Extrusion (applicable to RHS aluminum alloy)

Mandel punching machine (used for steel, but rarely used due to high cost)

3. Post-processing and organizing

Heat treatment (if strength/ductility is required).

Surface treatment:

Galvanizing (hot-dip galvanizing or electroplating) for corrosion resistance.

Paint/powder coating for aesthetic and protective purposes.

Passivation (applicable to stainless steel RHS).

Testing and quality control

Ultrasonic testing for welding integrity (UT)

Dimensional inspection (width, thickness, straightness).

Mechanical tests (tensile strength, yield strength).

4. Standards and Grades

RHS is produced in accordance with the following international standards:

ASTM A500 (Carbon steel, structural pipe)

EN 10219 (Hollow profiles with Cold-formed Welded Structures)

JIS G 3463 (Japanese Welding RHS Standard)

AS/NZS 1163 (Australian/New Zealand Standard)

The Application of Rectangular hollow sections(RHS):

Rectangular hollow sections (RHS) are widely used in construction and engineering due to their structural efficiency, aesthetics and versatility. The following are some key applications:

Architecture and building

Structural frame: Due to its high strength-to-weight ratio, RHS is typically used in beams, columns and trusses of buildings, Bridges and industrial structures.

Roof and facade systems: Its clean lines and smooth surfaces make it an ideal choice for modern architectural design, including canopies, sunshades and curtain walls.

Modular construction: Prefabricated structures (such as temporary shelters, modular houses) benefit from RHS due to their ease of assembly and transportation.

2. Infrastructure and Civil Engineering

Bridges and sidewalks: RHS provides excellent load-bearing capacity for pedestrian overpasses, sign supports and highway gantries.

Support structure: Used for transmission towers, lamp posts, traffic signal frames, etc.

3. Automobiles and Transportation

Chassis and roller frames: RHS is used in vehicle frames (for example, buses, trailers and off-road vehicles) due to its torsional stiffness and impact resistance.

Railway and metro systems: used for platform edges, escalator supports and train bogies.

4. Industrial applications

Mechanical and equipment frames: RHS provides strong support for conveying systems, robotic arms and heavy machinery.

Storage racks and mezzanines: Their uniform shape can effectively utilize the space of the warehouse.

5. Furniture and Urban Design

Benches, bollards and signs: RHS offers durability and a smooth look for street furniture.

Playground and gym equipment: resistant to weathering and corrosion (especially when galvanized or stainless steel is used).

6. Renewable energy

Solar panel installation: RHS is used in solar farm structures due to its strength and ease of manufacturing. 1) All the equipment on the entire production line is equipped with the function of being networked with the computer data acquisition system, enabling real-time data transmission. The technical parameters during the production process are controlled by the central control room.

The steel pipe has longitudinal welds, and both the inner and outer welds are welded by submerged arc welding.

2) After the steel pipe undergoes the overall mechanical expansion process, the internal stress is small and evenly distributed, which can effectively prevent stress corrosion cracking, has high dimensional accuracy and is convenient for on-site welding construction.

3) After pre-welding, precise welding technology is adopted, ensuring a stable welding process and high weld quality.

4) The weld seams are convenient for non-destructive testing during the production process and for on-site non-destructive testing and re-inspection during use.

5) The product specification range is wide. We can produce both small-diameter and large-wall-thickness steel pipes as well as large-diameter and large-wall-thickness steel pipes.

The advantages of RHS:

High strength and rigidity - resistant to bending and torsional forces.

Lightweight - Compared with the solid part, it is easier to transport and install.

Aesthetic appeal - Clean, modern exposed structure.

Easy to manufacture - can be welded, bolted or machined easily.

Corrosion-resistant - made of stainless steel or aluminium.

RHS can be used on materials such as carbon steel, stainless steel and aluminum, and can be galvanized or powder-coated to enhance durability.

Name: Crystal

Mobile:86-18602606269

Tel:86-18602606269

Whatsapp:8618602606269

Email:crystal@yashanway.com

Add:B-508, Xiangnian Plaza, Dongjiang Road, Hexi District, Tianjin, China

Copyright © 2013-2022 TIANJIN BINHAI YASHANWAY IMPORT AND EXPORT CO., LTD All Rights Reserved. https://www.zzshe.com/Blog/100.html