Category:

MS LSAW Pipes

OD: 219-1625MM

Grade: Q195,Q215,Q235,Q345, S275JR, S355JR, 355JOH, 355J2H

Thickness: 6-60mm

Surface: Oiled, Painted, Black, Galvanized

Product description:Longitudinal submerged arc welded pipes are further classified into three types based on their forming methods: UOE, RBE, and JCOE. Longitudinal high-frequency welded steel pipes have the characterist

ASTM A671 LSAW Pipe Manufacturers Submerged ARC Welding Technology

Item

LSAW Steel Pipe

OD

219-1625mm

Thickness

6-60mm

Applicant

Fluid Pipe, Boiler Pipe, Drill Pipe, Hydraulic Pipe, Gas Pipe, OIL PIPE, Chemical Fertilizer Pipe

Alloy or Not

Non-Alloy

Section Shape

Round

Standard

BS, GB, EN, JIS

Grade

Q195,Q215,Q235,Q345, S275JR, S355JR, 355JOH, 355J2H

Surface Treatment

Hot Rolled

Oiled or Non Oiled

Non-oiled

Delivery Time

15-30 days

Surface

Blace, Oild, Painted, Galvanized

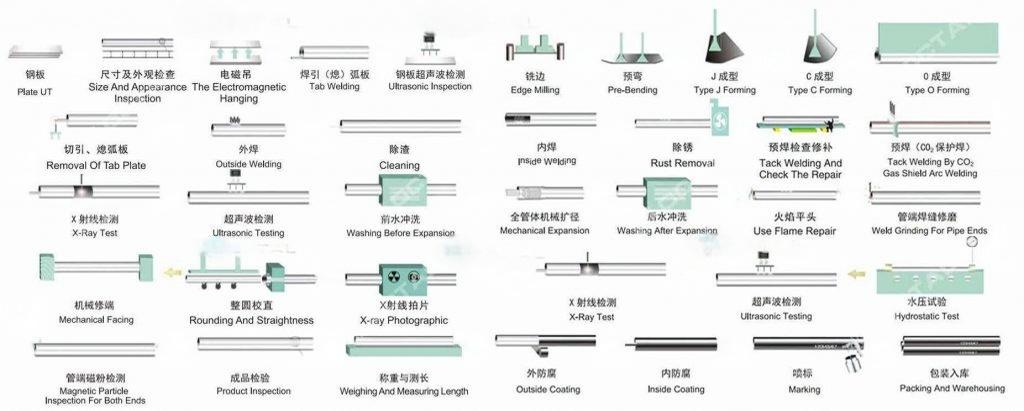

LSAW Pipe Production process:

1. Plate probe: It is used for the manufacturing of large-diameter LSAW joints after they enter the production line. This is the initial full-board ultrasonic testing.

2. Milling: The machine used for milling accomplishes this operation by milling the sheet with both edges to meet the requirements of the sheet's width and parallel shape and degree on the sides.

3. Pre-bent surface: This surface is achieved by using a pre-bending machine on the edge of the pre-bent plate. The edges of the sheet material need to meet the curvature requirements.

4. Forming: After the pre-bending process, in the front half of the JCO forming machine, the steel plate is pressed into a "J" shape, while in the other half of the same steel plate, it is bent and pressed into a "C" shape. Finally, an opening is made to form an "O" shape.

5. Pre-welding: This is to form a straight seam after the welded pipe steel is formed, and then continuously weld it with a gas seam (MAG).

6. Internal welding: Series multi-wire submerged arc welding (about four wires) is carried out inside the straight seam welded steel pipe.

7. External welding: External welding is a series multi-wire submerged arc welding carried out on the outside of LSAW steel pipes.

8. Ultrasonic flaw detection: 100% inspection is carried out on both the inner and outer surfaces of straight seam welded steel pipes and on both sides of the base material.

9. X-ray inspection: An image processing system is used to conduct X-ray industrial television inspection both inside and outside to ensure detection sensitivity.

10. Reaming: It is used to complete the long hole diameter of submerged arc welded and straight seam steel pipes to improve the dimensional accuracy of the steel pipes and improve the distribution of stress in the steel pipes.

11. Hydraulic test: To ensure that the steel pipes meet the standard requirements, hydraulic tests are conducted on the steel hydraulic testing machine after the root expansion test, which has the functions of automatic recording and storage.

12. Chamfering: This involves the inspection of the steel pipe at the end of the entire process.

Weld seam treatment

If the gap is too large, the proximity effect will be reduced, the eddy current heat will be insufficient, and the weld seam will not fuse or crack due to poor intergranular joints.

2. If the gap is too small, the proximity effect increases, resulting in excessive heat generation during welding and causing the weld seam to burn out. Otherwise, deep pits will form in the weld seam after extrusion and rolling, affecting the surface quality of the weld seam.

After the two edges of the tube blank are heated to the welding temperature, under the extrusion of the extrusion roller, a common metal grain interpenetrates and crystallizes, and finally a firm weld seam is formed. If the extrusion force of the spiral steel pipe is too small, the number of common crystals formed will be small, the strength of the weld metal will decrease, and cracks will occur after being subjected to force. If the extrusion force is too large, the molten metal will be extruded from the weld seam. Not only does it reduce the strength of the weld seam, but it also generates a large number of internal and external burrs, and even causes defects such as weld overlap.

The main technological features of lsaw steel pipes:

1) All the equipment on the entire production line is equipped with the function of being networked with the computer data acquisition system, enabling real-time data transmission. The technical parameters during the production process are controlled by the central control room.

The steel pipe has longitudinal welds, and both the inner and outer welds are welded by submerged arc welding.

2) After the steel pipe undergoes the overall mechanical expansion process, the internal stress is small and evenly distributed, which can effectively prevent stress corrosion cracking, has high dimensional accuracy and is convenient for on-site welding construction.

3) After pre-welding, precise welding technology is adopted, ensuring a stable welding process and high weld quality.

4) The weld seams are convenient for non-destructive testing during the production process and for on-site non-destructive testing and re-inspection during use.

5) The product specification range is wide. We can produce both small-diameter and large-wall-thickness steel pipes as well as large-diameter and large-wall-thickness steel pipes.

Name: Crystal

Mobile:86-18602606269

Tel:86-18602606269

Whatsapp:8618602606269

Email:crystal@yashanway.com

Add:B-508, Xiangnian Plaza, Dongjiang Road, Hexi District, Tianjin, China

Copyright © 2013-2022 TIANJIN BINHAI YASHANWAY IMPORT AND EXPORT CO., LTD All Rights Reserved. https://www.zzshe.com/Blog/100.html