Category:

MS SSAW Pipes

OD: 21-4064MM

Grade: Q195,Q215,Q235,Q345, S275JR, S355JR, 355JOH, 355J2H

Thickness: 3-150mm

Surface: Oiled, Painted, Black

Product description:Definition and Explanation of SSAW Pipes. SSAW pipes, also known as spiral submerged arc welded pipes, are manufactured using a spiral welding process. This method ensures a consistent and uniform wel

Spiral Welded Pipe Weight Chart In China

Item

Spiral Welded Steel Pipe

OD

21-4064mm

Thickness

3-150mm

Applicant

Fluid Pipe, Boiler Pipe, Drill Pipe, Hydraulic Pipe, Gas Pipe, OIL PIPE, Chemical Fertilizer Pipe

Alloy or Not

Non-Alloy

Section Shape

Round

Standard

BS, GB, EN, JIS

Grade

Q195,Q215,Q235,Q345, S275JR, S355JR, 355JOH, 355J2H

Surface Treatment

Hot Rolled

Oiled or Non Oiled

Non-oiled

Delivery Time

15-30 days

Surface

Blace, Oild, Painted

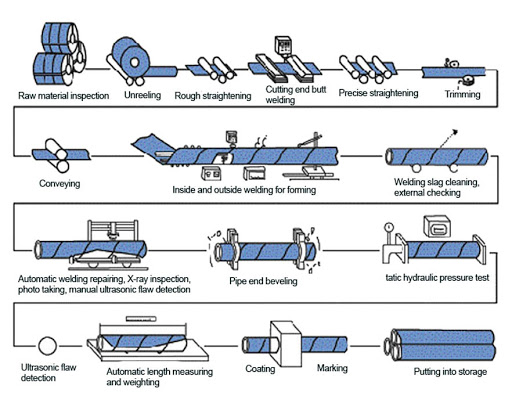

SSAW Pipe Production process:

(1) Raw materials: Steel strip coils, welding wires, flux. Strict physical and chemical examinations are required before investment.

(2) For the head and tail butt joints of steel strips, single wire or double wire submerged arc welding is adopted. After being rolled into steel pipes, automatic submerged arc welding is used for repair welding.

(3) Before forming, the strip material undergoes leveling, trimming, planing, surface cleaning and conveying, and pre-bending treatment.

(4) Electrical contact pressure gauges are adopted to control the pressure of the cylinders on both sides of the conveyor to ensure the smooth transportation of the strip material.

(5) Adopt external control or internal control roller forming.

(6) A weld gap control device is adopted to ensure that the weld gap meets the welding requirements, and the pipe diameter, misalignment, and weld gap are all strictly controlled.

(7) Both the inner and outer welding are carried out using single-line or double-line submerged arc welding with Lincoln electric welding machines from the United States, ensuring stable welding quality.

(8) After welding, the weld seam is inspected by an online continuous ultrasonic automatic flaw detector to ensure that the non-destructive testing coverage rate of the spiral weld seam is 100%. If there are any defects, an automatic alarm will be triggered and marks will be sprayed. Production workers can adjust the process parameters at any time based on this to eliminate the defects promptly.

(9) Use an air plasma cutting machine to cut the steel pipes into single pieces.

(10) After each batch of steel pipes is cut into individual steel pipes, they must undergo a strict initial inspection system to check the mechanical properties, chemical composition, weld fusion condition, surface quality, etc. of the steel pipes, and pass non-destructive testing to ensure that the pipe-making process is qualified. After that, it can be officially put into production.

(11) For the areas on the weld seam with continuous acoustic wave flaw detection marks, re-inspect with artificial ultrasound and X-rays. If there are any defects, repair them and then conduct non-destructive testing again until it is confirmed that the defects have been eliminated.

(12) The pipes at the butt welds of the steel strips and the D-shaped joints where they intersect with the spiral welds shall all be inspected by X-ray television or video.

(13) Each steel pipe undergoes a hydrostatic test, and the pressure is sealed radially. The test pressure and time are strictly controlled by the steel pipe hydraulic microcomputer detection device. The test parameters are automatically printed out.

(14) In the processing of pipe ends, the verticality, bevel and dull edge of the end face must be precisely controlled

Weld seam treatment

If the gap is too large, the proximity effect will be reduced, the eddy current heat will be insufficient, and the weld seam will not fuse or crack due to poor intergranular joints.

2. If the gap is too small, the proximity effect increases, resulting in excessive heat generation during welding and causing the weld seam to burn out. Otherwise, deep pits will form in the weld seam after extrusion and rolling, affecting the surface quality of the weld seam.

After the two edges of the tube blank are heated to the welding temperature, under the extrusion of the extrusion roller, a common metal grain interpenetrates and crystallizes, and finally a firm weld seam is formed. If the extrusion force of the spiral steel pipe is too small, the number of common crystals formed will be small, the strength of the weld metal will decrease, and cracks will occur after being subjected to force. If the extrusion force is too large, the molten metal will be extruded from the weld seam. Not only does it reduce the strength of the weld seam, but it also generates a large number of internal and external burrs, and even causes defects such as weld overlap.

The main technological features of spiral steel pipes:

During the forming process, the steel plate deforms uniformly, has small residual stress, and no scratches occur on the surface. The processed spiral steel pipes have greater flexibility in terms of the size and specification range of diameter and wall thickness, especially when producing high-grade thick-walled pipes, particularly those with medium and small diameters. It has advantages that other processes cannot match and can meet the needs of users. There are quite a few specification requirements for spiral steel pipes.

b. Advanced double-sided submerged arc welding technology is adopted, which can achieve welding at the optimal position, and is less likely to have defects such as misalignment, weld deviation, and incomplete penetration. The welding quality is easy to control.

c. 100% quality inspection of steel pipes is carried out to ensure that the entire production process of steel pipes is effectively inspected and monitored, effectively guaranteeing product quality.

All the equipment on the entire production line is equipped with the function of being networked with the computer data acquisition system, enabling real-time data transmission. The technical parameters during the production process are controlled by the central control room.

Name: Crystal

Mobile:86-18602606269

Tel:86-18602606269

Whatsapp:8618602606269

Email:crystal@yashanway.com

Add:B-508, Xiangnian Plaza, Dongjiang Road, Hexi District, Tianjin, China

Copyright © 2013-2022 TIANJIN BINHAI YASHANWAY IMPORT AND EXPORT CO., LTD All Rights Reserved. https://www.zzshe.com/Blog/100.html