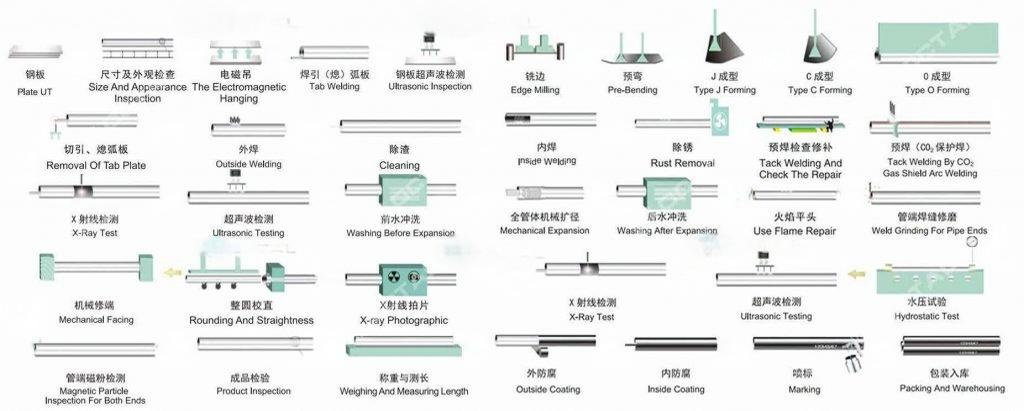

1. Plate probe: It is used for the manufacturing of large-diameter LSAW joints after they enter the production line. This is the initial full-board ultrasonic testing.

2. Milling: The machine used for milling accomplishes this operation by milling the sheet with both edges to meet the requirements of the sheet's width and parallel shape and degree on the sides.

3. Pre-bent surface: This surface is achieved by using a pre-bending machine on the edge of the pre-bent plate. The edges of the sheet material need to meet the curvature requirements.

4. Forming: After the pre-bending process, in the front half of the JCO forming machine, the steel plate is pressed into a "J" shape, while in the other half of the same steel plate, it is bent and pressed into a "C" shape. Finally, an opening is made to form an "O" shape.

5. Pre-welding: This is to form a straight seam after the welded pipe steel is formed, and then continuously weld it with a gas seam (MAG).

6. Internal welding: Series multi-wire submerged arc welding (about four wires) is carried out inside the straight seam welded steel pipe.

7. External welding: External welding is a series multi-wire submerged arc welding carried out on the outside of LSAW steel pipes.

8. Ultrasonic flaw detection: 100% inspection is carried out on both the inner and outer surfaces of straight seam welded steel pipes and on both sides of the base material.

9. X-ray inspection: An image processing system is used to conduct X-ray industrial television inspection both inside and outside to ensure detection sensitivity.

10. Reaming: It is used to complete the long hole diameter of submerged arc welded and straight seam steel pipes to improve the dimensional accuracy of the steel pipes and improve the distribution of stress in the steel pipes.

11. Hydraulic test: To ensure that the steel pipes meet the standard requirements, hydraulic tests are conducted on the steel hydraulic testing machine after the root expansion test, which has the functions of automatic recording and storage.

12. Chamfering: This involves the inspection of the steel pipe at the end of the entire process.

Name: Crystal

Mobile:86-18602606269

Tel:86-18602606269

Whatsapp:8618602606269

Email:crystal@yashanway.com

Add:B-508, Xiangnian Plaza, Dongjiang Road, Hexi District, Tianjin, China

Copyright © 2013-2022 TIANJIN BINHAI YASHANWAY IMPORT AND EXPORT CO., LTD All Rights Reserved. https://www.zzshe.com/Blog/100.html